Currently Empty: $0.00

Alloys of Embossed Aluminium Sheet

Alloys of embossed aluminium sheet comprise 1060, 3003, 5052 and 5083 etc. 1060 embossed aluminium sheet is able to withstand normal environments and is therefore usually applied as panels for flooring, refrigeration rooms and packaging shells. Superior embossed sheets have regular thickness, strength and anodized film in accordance with national standards. The thickness should be larger than 1.2mm, tensile strength stronger than 175N/mm2, yield strength bigger than 108N/mm2 and anodized film thicker than 10um. If a piece of embossed aluminium sheet can not reach any of the standards above, it’s regarded as a defective product.

3003 embossed aluminium sheet is also called Alu-Mag embossed sheet. It’s made of 3003 aluminum, and has good corrosion resistance and harder strength than 1060. In spite of its fame as an anti-corrosion sheet, it can not compete with 5000 series in corrosion resistance. Therefore, it’s more frequently applied as raw material for products of loose anti-rust requirements, such as truck bodies, refrigeration house floors and so on. In contrast, 5052 and 5083 embossed aluminium sheet boast excellent anti-corrosion property and hard strength. They are more suitable for special applications like moist ships and vehicle compartments.

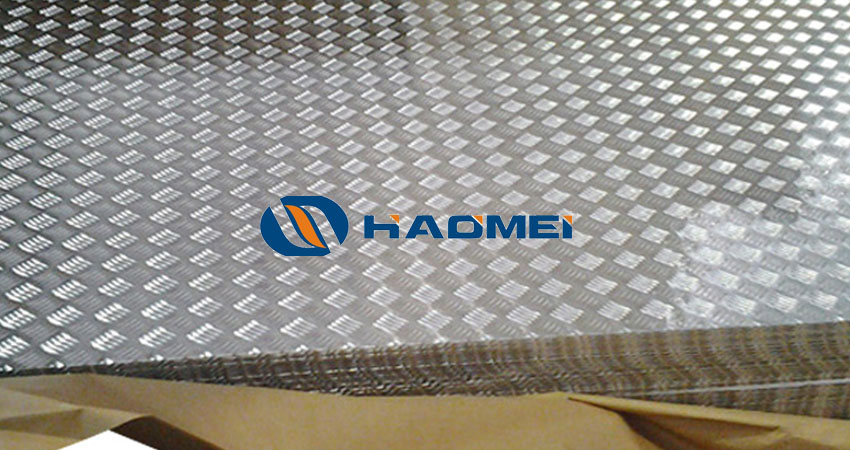

In addition, superior and inferior embossed aluminium sheets differ in properties. Sheets from normal manufacturers are of top class base plates, bright clean surfaces, clear regular patterns and flat straight shapes. On the other hand, small suppliers usually offer sheets of scrap aluminum, dull surface, irregular patterns and unqualified properties.