Currently Empty: $0.00

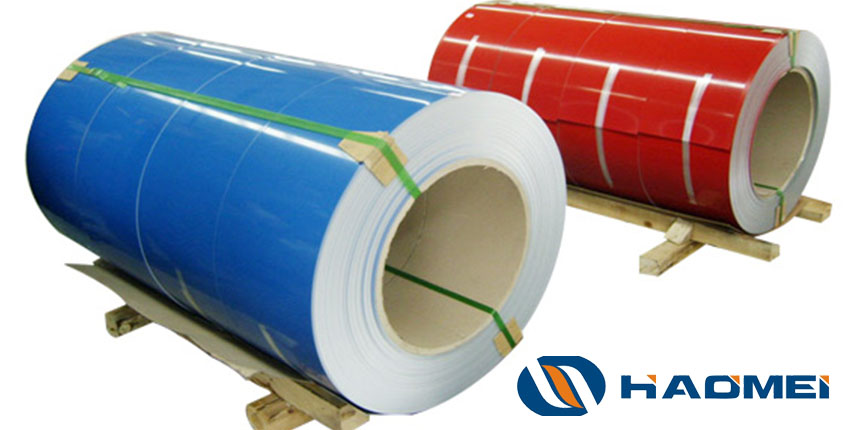

Application of 3005 Painted Aluminum Coil

3005 painted aluminum coil belongs to the series of aluminum manganese alloys. Its strength ranks behind most other alloys except 1000 series and 3003. About 20% harder than 3003 aluminum coil, it’s widely used in production requiring medium strength. It can not be heat treated, and cold working is the only way to improve its mechanical properties. It shows highest work-ability at O state and lowest work-ability after cold hardening. With an manganese content between 1% and 1.5%, it has excellent corrosion resistance, good deep drawing property, satisfying formability and normal welding property.

3005 painted aluminum coil is among the most widely applied aluminum coil stocks. It can be processed into thin cans for beer, liquid food, beverages etc. The inner side of the cans is usually painted with a thin layer of protective film that separates aluminum and contained food apart. The fact is, aluminum metal does not react with liquid food unless it’s acid. Its wide application in cookware is a good example. 3005 painted aluminum coil serves as raw material for trailer tanks containing chemicals and oil as well. Light weight and low price makes it more popular than steel with trailer manufacturers. It’s said that there are even “all-aluminum” trailers, the weight of which could be 3 tons lighter than steel ones. Lighter weight means less energy consumption and more loading weight. Air conditioner tubes are the third example of 3005 painted aluminum coil. This application takes full advantage of its strong corrosion resistance, because air conditioner outlets water during operation. Light weight also helps to reduce total weight of an air conditioner.

As an experienced aluminum coil and sheet manufacturer, we supply 3005 painted aluminum coil of competitive price. Welcome to contact us at april@aluminumhm.com for more information!