Currently Empty: $0.00

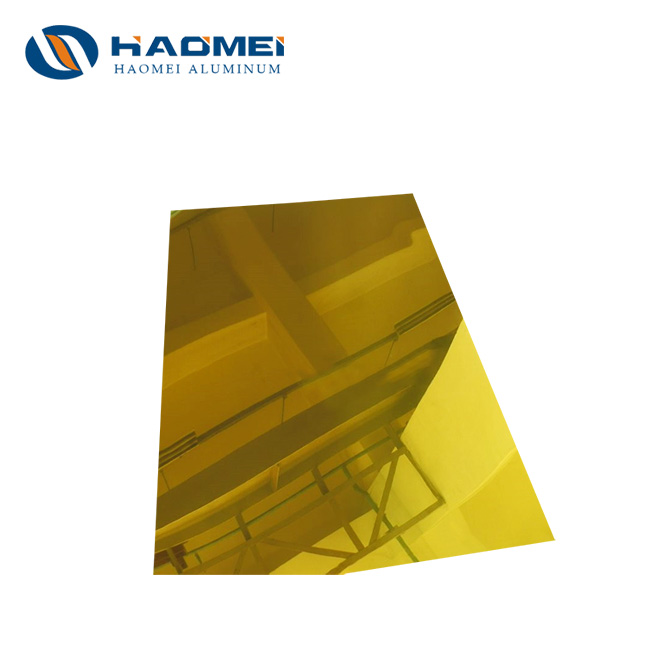

Category of Mirror Finish Aluminum Sheet Coil Raw Material

No matter what kind of aluminum product it is, its quality largely depends on that of its raw materials, especially aluminum materials. Speaking of mirror finish aluminum sheet, most people would think of alloys of 1xxx, 3xxx and 5xxx series, yet are you clear about their real quality?

Generally speaking, the base plate of a qualified piece of mirror finish aluminum sheet should be between 0.3mm and 0.5mm thick. Mirror aluminum sheet coil rolls of superior brands are all around 0.5mm thick. The best category of raw material is aluminum magnesium alloy which contains a slight content of manganese. This type of alloy boasts excellent corrosion resistance. Owing to its content of manganese, it has the necessary hardness and strength as an ideal raw material for aluminum ceiling tiles. The second is aluminum manganese alloy, which has a better strength but weaker corrosion resistance than aluminium magnesium alloy. However, if both sides of this alloy of sheets are treated properly, its corrosion resistance can be improved effectively. Another kind of base plate, although also called aluminum alloy, it has little contents of manganese and magnesium. Thus it can not compete with either of the two alloy types mentioned above. Owing to its low hardness, it’s very easy to be processed. As long as it’s thick enough, it can meet the basic flatness of the aluminum ceiling tile. The fourth type of alloy, known as the common alloy, has poor mechanical properties. Recycled aluminum alloy plates have the poorest quality, because there’s no basic control of chemical elements, which leads to uneven surface and easy deformation of the sheets.