Currently Empty: $0.00

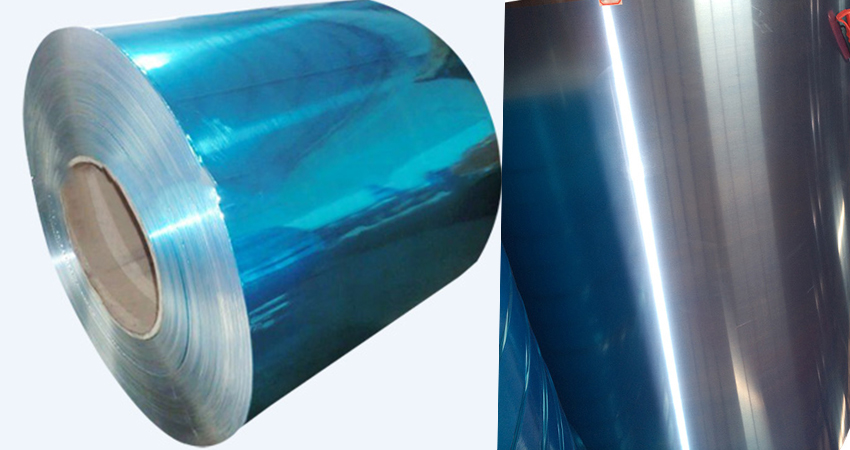

How to Avoid Surface Damage of Aluminum Coil

Surface damage of aluminum coil is a common problem in production and storage of aluminium rolls. Generally speaking, the problem roots in three possible reasons. First, some precipitates may be left on the surface during the manufacturing process, and if these precipitates have not go through homogenizing treatment or have gone through ineffective homogenizing treatment, metal particles will be left on the surface and then damage the aluminum coil during the extrusion process. Second, the molds may be have impurities or particles that further damage the coils during the manufacturing process. Third, the damaged can also be caused in the process of removing aluminium rolls off the discharge rail to the swing bed, because fork bars are used here and they are likely to damage the coil surface.

Therefore, the surface of aluminum coils may be damaged from the beginning to the end of the whole production process. Manufacturers should take corresponding measures to avoid such a problem. The molds must be clean before going into work. The homogenizing treatment must be carried out completely and effectively, and finished coils must be moved carefully.

The three aspects mentioned are only usual reasons for surface damage of aluminum coils in production. Many other reasons may cause the problem as well. Haomei supplies aluminum coil 3005, 3003, 1050, 1060, 1070, 1100, 5052, 5082 and 5083 etc. We have exported our products to over thirty countries around the world. If you are in need of aluminum products, welcome to contact us for more information!