Currently Empty: $0.00

Mechanical Processes of Mirror Reflector Aluminum Sheet

Mechanical processes of mirror reflector aluminum sheet include material removal method and non-cutting method. The former further includes peeling, grinding, polishing and electrical sparkling. The latter comprises rolling and extruding. The adoption of material removal method must be based on the following conditions. The first is huge investment in expensive equipment. Some grinding machines cost over 1 million RMB and more. The second are experienced works who are able to operate the advanced machines skillfully and deal with common technical problems. The third is spacious workshop convenient for production processes. The fourth are large quantities of cooling and lubricating oil and liquid. The fifth are expensive grinding wheels. The last entails waste treatment with a purpose to protect the environment.

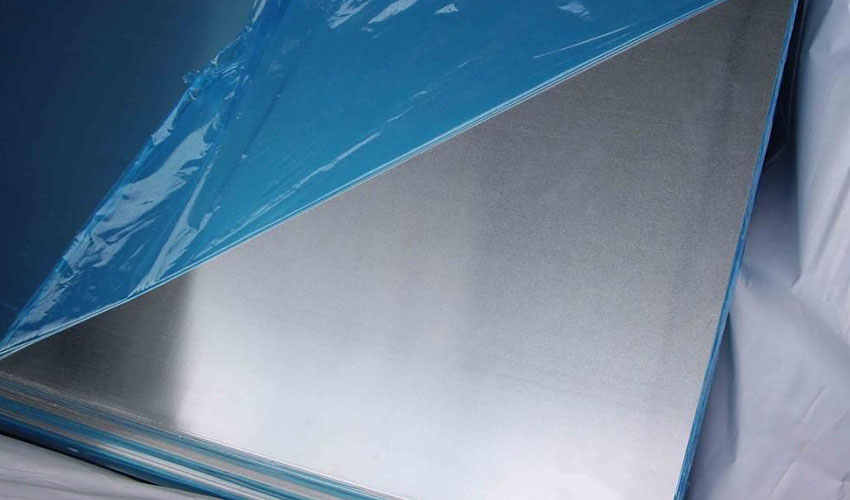

With fast development of engineering construction and manufacturing industries, mirror reflector aluminum sheet is more and more widely applied. The application scope covers industries of lamp parts, light ornaments, solar reflective materials, interior decoration, exterior wall cladding, home appliance facial panels, electronic products shells, furniture, cupboards, automobile ornaments, labels, trading marks, cases, bags, jewellery cases etc. Mirror reflector aluminum sheet is mostly obtained by multiple processing methods of rolling, polishing and milling on base plates of 1xxx, 3xxx and 5xxx series aluminum. Both rolls and sheets are available. The surface of the sheet takes on a mirroring effect like a glass mirror. In addition, some manufacturers supply color coated mirror reflector aluminum sheet as well. Relative colors include basic colors and metal colors. The former are natural colors like red, blue, green, brown etc, and the latter generally include existing colors of metals like gold, silver, copper and titanium, making the aluminium sheets look like a different metal of the painted color on its surface.