Currently Empty: $0.00

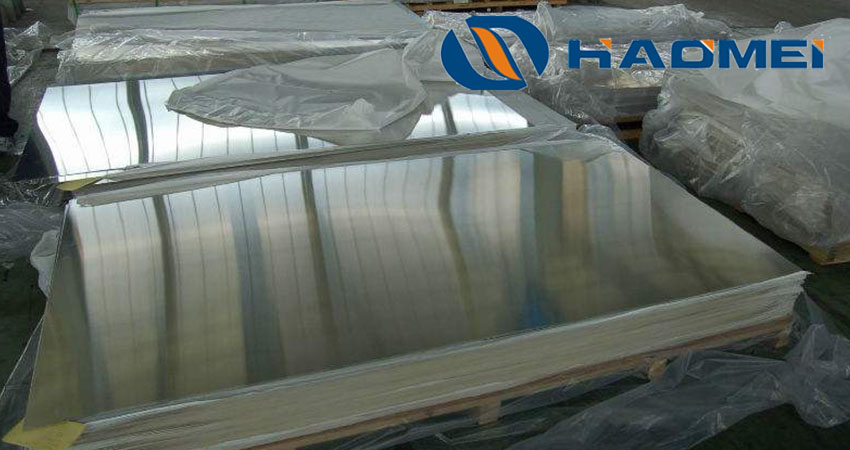

Possible Problems for Production of Mirror Finish Anodized Aluminum Sheet

This articles aims to discuss three possible problems for production of mirror finish anodized aluminum sheet: astigmatism loss, existence of impurities and emergence of sealed holes.

The astigmatism loss of mirror reflector aluminum sheet may result from various factors involving base plate quality, base sheet model and anodized film type etc. Owing to wide application of the sheet, users should choose base plates in accordance with specific requirements. Some types of anodized film tend to lead to astigmatism loss. These factors should all taken to be account to obtain ideal reflectivity of the sheet.

Existence of impurities prove to be a common problem in production of mirror finish anodized aluminum sheet. This mainly results from low quality of raw materials. In other words, the raw materials contain too much impurities. Therefore, an effective solution is to keep adopting high purity aluminum base sheets for production. Of course, this will lead to rise in cost and eventual price. If you can not accept that, you will be confronted with a real dilemma.

To avoid the emergence of sealed holes you need to keep strict control of temperature and time in the anodizing process. Appropriate ratios should be adjusted to realize the best effect. Purchases should also list sealed holes as a factor in selecting aluminum mirror sheets. In addition, excessive content of assistant elements is also likely to lead to the appearance of sealed holes.